- Suspension sprayed chromium oxide coatings are an environmentally friendly and longer lasting hard chrome replacement.

- Because of the nano structured coating, in comparison to conventional sprayed chromium oxide crack propagation is limited and the hardness is higher.

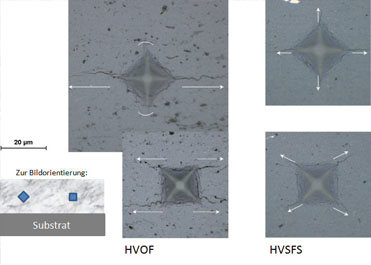

- The picture shows conventionally sprayed chromium oxide with cracks parallel to the coating, whilst cracks in a suspension sprayed chromium oxide coating spread evenly in all directions. In addition, the spreading of the cracks is less strong. For this reasons the wear resistance of the coating increases.

|

[Application: wear-resistant coating for piston rods] [Application: wear-resistant coating for piston rods]

Source: A. Killinger, A. Rempp, P. Müller, A. Manzat und R. Gadow,

Hochgeschwindigkeitsflammspritzen mit Suspensionen

aus nano- und submikronskaligen Oxidpulvern

High-velocity oxy-fuel spraying with suspensions

consisting of nanoscale and submicronscale oxide

powders

in: Thermal Spray Bulletin to be published in 2015

Hrsg. GTS eV

|